Gorle Global Group is a leader in the rollout of Optical Fiber Cable (OFC) networking, providing comprehensive solutions for both Outside Plant (OSP) and Inside Plant (ISP) optical fiber cables. Our approach ensures robust, high-performance network infrastructure tailored to meet diverse communication needs.

Key Components of OFC Rollout

OSP OFC (Outside Plant Optical Fiber Cable)

- Overview: OSP OFC is designed for outdoor applications and is crucial for long-distance data transmission. It is engineered to withstand harsh environmental conditions, including extreme temperatures, moisture, UV radiation, and mechanical stresses.

Installation Process

- Route Planning: Identify and plan the optimal route for outdoor cable deployment, considering geographical and environmental factors.

- Trenching and Ducting: Excavate trenches and install protective ducts to house the optical fiber cables. This step ensures durability and protection of the cables.

- Cable Blowing: Use advanced blowing techniques to insert the cables into the ducts, facilitating efficient and precise placement over long distances.

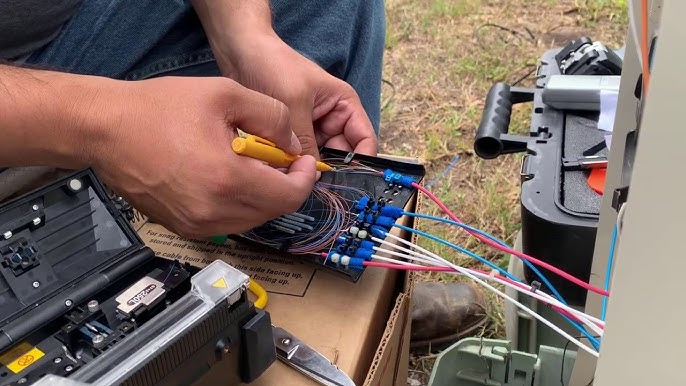

- Splicing and Testing: Perform splicing to join cable segments and conduct end-to-end testing to ensure signal integrity and performance.

Interior Design

- Space Planning: Designing functional and aesthetically pleasing interior spaces for homes, offices, and commercial establishments.

- Material and Finish Selection: Recommending high-quality materials and finishes that enhance the overall design and meet client preferences.

ISP OFC (Inside Plant Optical Fiber Cable)

Overview

ISP OFC is used within buildings and data centers for connecting and managing internal network infrastructure. It supports high-speed data transfer and is essential for maintaining efficient and reliable communication systems.

Installation Process:

- Network Design: Design the internal network layout to accommodate data centers, server rooms, and communication rooms, ensuring optimal cable routing and management.

- Cable Management: Install optical fiber cables within conduits, trays, or ducts inside buildings, ensuring neat and organized routing to minimize interference and maintain accessibility.

- Splicing and Termination: Perform splicing to connect cable segments and terminate the cables at distribution panels, ensuring accurate and reliable connections.

- Testing and Certification: Conduct thorough testing to verify the performance of the internal network, including signal quality, attenuation, and bandwidth. Obtain necessary certifications to ensure compliance with industry standards.

Applications

Data centers, office buildings, server rooms, and internal network infrastructure.

Additional Considerations

- Quality Assurance: Implement rigorous quality control and testing procedures to ensure the highest standards of performance and reliability for both OSP and ISP OFC installations.

- Compliance: Adhere to relevant industry standards and regulations to ensure that all installations meet technical and safety requirements.

- Project Management: Utilize effective project management practices to oversee all phases of the OFC rollout, ensuring timely completion, budget adherence, and seamless integration of network components.

Applications

Telecommunications networks, long-haul data transmission, ISP backbones, metropolitan area networks (MAN), and fiber-to-the-home (FTTH) deployments.

Gorle Global Group is dedicated to delivering high-quality Optical Fiber Cable (OFC) networking solutions, providing robust and reliable infrastructure for both outdoor and indoor applications to support modern communication needs.