Project Name: Drilling, Blasting, and Removal of Boulders for Road Project

Location: Nagpur-Mumbai Super Communication Expressway Road Project

Overview: The Drilling, Blasting, and Removal of Boulders project is a critical component of the Nagpur-Mumbai Super Communication Expressway Road Project, one of India's most ambitious infrastructure undertakings. This project focuses on the safe and efficient removal of large boulders and rock formations that obstruct the construction of the expressway. By employing advanced drilling and blasting techniques, the project aims to clear the path for this crucial roadway, ensuring smooth and timely progress in the construction of the expressway.

Highlights:

- Advanced Drilling Techniques: Utilization of state-of-the-art drilling equipment to precisely target and prepare boulders for blasting.

- Controlled Blasting Operations: Implementation of controlled blasting methods to ensure safety and minimize environmental impact, including vibration control and dust suppression.

- Efficient Boulder Removal: Deployment of heavy machinery for the quick and efficient removal of blasted boulders, facilitating the uninterrupted progress of the expressway construction.

Impact: This project plays a vital role in the timely completion of the Nagpur-Mumbai Super Communication Expressway, a major transportation artery that will significantly reduce travel time between Nagpur and Mumbai. By overcoming geological challenges, the project ensures the expressway's route remains safe and accessible, contributing to the region's economic growth and infrastructure development. Additionally, the use of controlled blasting techniques minimizes environmental disruption, setting a standard for responsible construction practices in large-scale infrastructure projects.

About Us

Project Name: Unused Boulders Crushing by Mobile Crushers for Road Project

Location:Nagpur-Mumbai Super Communication Expressway Road Project

Overview: The Unused Boulders Crushing by Mobile Crushers project is a vital initiative within the Nagpur-Mumbai Super Communication Expressway Road Project. This project focuses on repurposing unused boulders from the construction site by utilizing mobile crushers to convert them into valuable aggregates for road construction. By recycling these materials on-site, the project aims to optimize resource use, reduce waste, and contribute to the sustainability of the expressway's construction.

Highlights:

- Resource Optimization: The project effectively repurposes unused boulders, turning potential waste into a valuable resource for road construction.

- Mobile Crushing Units: The use of mobile crushers allows for flexible and efficient processing of boulders directly at the site, reducing the need for transporting materials to and from the project location.

- Sustainable Practices: By recycling existing materials, the project minimizes the environmental impact associated with sourcing new aggregates, promoting a more sustainable approach to infrastructure development.

Impact: The Unused Boulders Crushing by Mobile Crushers project plays a crucial role in the sustainable construction of the Nagpur-Mumbai Super Communication Expressway. By efficiently utilizing resources already available at the site, the project reduces material costs, decreases environmental impact, and ensures a steady supply of high-quality aggregates for the expressway. This approach not only supports the timely completion of the project but also sets a precedent for sustainable practices in large-scale infrastructure development.

Project Name: Crushed Sand Washing

Location:Nagpur-Kolhapur Road Project

Overview: The Crushed Sand Washing project on the Nagpur-Kolhapur Road is a groundbreaking initiative aimed at revolutionizing the sand processing industry. This state-of-the-art project involves the development of a washing plant designed to optimize the operations of a cutting-edge crushed sand washing facility. By employing advanced technologies, the project seeks to enhance the efficiency, quality, and sustainability of sand production in the region.

Highlights:

- Innovative Washing Technology: The project utilizes advanced washing technology to ensure the production of high-quality crushed sand, meeting stringent industry standards.

- Water Recycling Systems: Equipped with sophisticated water recycling systems, the plant minimizes water usage, promoting environmental sustainability.

- Energy Efficiency: The facility is designed to operate with high energy efficiency, reducing operational costs and environmental impact.

Impact: The Crushed Sand Washing project has the potential to transform the sand production industry in the region. By improving the quality and consistency of crushed sand, the project supports the construction and infrastructure sectors, contributing to more durable and sustainable buildings and roads. Additionally, the project's focus on water conservation and energy efficiency helps reduce its environmental footprint, setting a new benchmark for eco-friendly industrial practices.

Project Name: Sand Production from Unused Boulders using Mobile Crushers for Road Project

Location:Development of Chamrajnagar Industrial Area (KIDC), Chamrajnagar, Karnataka

Overview: The Sand Production from Unused Boulders project is a key initiative in the development of the Chamrajnagar Industrial Area (KIDC) in Karnataka. This project involves the use of mobile crushers to process unused boulders from the construction site, converting them into high-quality sand suitable for industrial and construction purposes. By efficiently utilizing available resources, the project aims to meet the demand for sand in the industrial area while promoting sustainable construction practices.

Highlights:

- Mobile Crushing Technology: The project deploys advanced mobile crushers capable of efficiently processing boulders into fine sand, directly on-site.

- Resource Efficiency: The initiative capitalizes on unused boulders, transforming them into valuable construction material, thereby reducing waste and the need for external sand sourcing.

- Quality Sand Production: The sand produced meets industry standards, ensuring it can be effectively used in various construction and industrial applications within the Chamrajnagar Industrial Area.

Impact: The Sand Production from Unused Boulders project significantly contributes to the sustainable development of the Chamrajnagar Industrial Area. By converting on-site boulders into usable sand, the project reduces the environmental impact associated with sand mining and transportation. This initiative not only supports the construction and infrastructure development within the industrial area but also promotes resource efficiency and environmental stewardship, setting a benchmark for future industrial projects in the region.

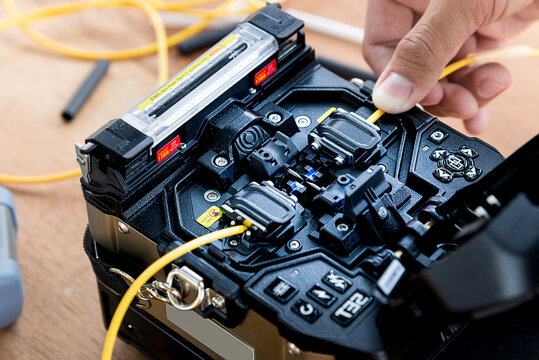

Project Name: OFC Gram Panchayat MahaNet-1 (BharatNet II) Project in Maharashtra

Location:Services of OFC Rollout in Pusad under Yavatmal District

Overview: The OFC (Optical Fiber Cable) Gram Panchayat MahaNet-1 project is a critical part of the BharatNet II initiative, aimed at connecting rural areas in Maharashtra to the digital world. This project focuses on the rollout of optical fiber cables in Pusad, under Yavatmal District, to provide high-speed internet connectivity to Gram Panchayats. By bridging the digital divide, the project seeks to empower rural communities with access to e-governance, education, healthcare, and other essential services.

Highlights:

- Extensive OFC Network: The project involves laying a robust network of optical fiber cables, ensuring high-speed internet connectivity across multiple Gram Panchayats in the Pusad region.

- Digital Inclusion: The initiative is designed to provide rural communities with access to digital infrastructure, enabling better communication, online services, and opportunities for economic development.

- Scalable Infrastructure: The OFC network is built with scalability in mind, allowing for future upgrades and expansions to meet increasing data demands.

Impact: The OFC Gram Panchayat MahaNet-1 project has a transformative impact on the rural areas of Pusad in Yavatmal District. By providing reliable and high-speed internet connectivity, the project enables Gram Panchayats to offer enhanced e-governance services, improve education and healthcare delivery, and promote economic development through digital inclusion. This initiative not only connects rural communities to the broader digital economy but also lays the foundation for sustainable growth and improved quality of life in the region.

Project Name: 10 MW (AC) Solar Power Plant Installation

Location:Kadri, Andhra Pradesh

Overview:The 10 MW (AC) Solar Power Plant Installation in Kadri, Andhra Pradesh, represents a significant step forward in the adoption of renewable energy in the region. This project involves the design, construction, and commissioning of a 10 MW (AC) solar power plant, aimed at harnessing solar energy to generate clean electricity. The plant is designed to supply power to the local grid, contributing to the state's energy needs while promoting environmental sustainability.

Highlights:

- Advanced Solar Technology: The project employs state-of-the-art photovoltaic (PV) modules and inverters to maximize energy production and efficiency.

- Grid Integration: The solar power plant is seamlessly integrated with the local grid, ensuring a stable and reliable supply of electricity to the surrounding areas.

- Sustainability: The project significantly reduces dependence on fossil fuels, contributing to lower carbon emissions and supporting Andhra Pradesh's renewable energy goals.

Impact: The installation of the 10 MW (AC) Solar Power Plant in Kadri has a profound impact on the region's energy landscape. By generating clean, renewable energy, the project helps reduce greenhouse gas emissions, contributing to the fight against climate change. It also supports local economic development by creating jobs during the construction and operational phases. Moreover, the project enhances energy security for the region, providing a reliable and sustainable source of electricity that benefits both the environment and the community.

Project Name: Metal Fabrication & Foundry

Location:MIDC, Nagpur, Maharashtra

Overview:At Empyreal Industries, the Metal Fabrication & Foundry project is dedicated to crafting high-quality metal products and engineering solutions. Situated in MIDC, Nagpur, Maharashtra, this facility sets new benchmarks for excellence in the industry. We specialize in the fabrication of precision-engineered components and structures, including world-class solar module installation systems. Our focus on innovation and sustainability drives us to use cutting-edge technology and practices to ensure the durability and efficiency of our products.

Highlights:

- Precision Metal Fabrication: The facility utilizes advanced technology to deliver high-precision metal fabrication for a wide range of applications, from industrial machinery to structural components.

- Foundry Excellence: State-of-the-art foundry operations ensure the production of high-quality metal castings, meeting rigorous industry standards.

- Renewable Energy Solutions: We manufacture robust solar module installation structures, contributing to the stability and efficiency of solar generation systems.

- Sustainability Focus: The project emphasizes sustainable practices, incorporating eco-friendly processes and materials to support a greener future.

Impact: The Metal Fabrication & Foundry project has a substantial impact on both the industry and the environment. Locally, it creates employment opportunities and stimulates economic growth within the MIDC area. Nationally, it enhances the quality and availability of critical engineering components and supports the renewable energy sector by providing reliable solar module structures. By prioritizing sustainability and innovation, the project contributes to the advancement of green technologies and the broader goal of environmental stewardship.

Project Name: Lithium-ion Battery Assembly Line

Location:Nagpur, Maharashtra

Overview:The Lithium-ion Battery Assembly Line project in Nagpur, Maharashtra, involves the establishment of a cutting-edge facility dedicated to the assembly of lithium-ion batteries. This project aims to enhance the local production capabilities for these high-energy-density batteries, which are crucial for powering a range of applications, including electric vehicles (EVs), renewable energy storage, and consumer electronics.

Highlights:

- Advanced Manufacturing Technology: The assembly line features state-of-the-art technology for precise and efficient battery production, including automated processes and quality control systems.

- High-Performance Batteries: The facility produces high-performance lithium-ion batteries known for their energy efficiency, long life cycle, and reliability.

- Scalability: The assembly line is designed with scalability in mind, allowing for future expansion to meet growing market demands and technological advancements.

Impact: The Lithium-ion Battery Assembly Line project has a significant impact on both the local and national levels. Locally, it creates job opportunities, stimulates economic growth, and positions Nagpur as a hub for advanced battery manufacturing. Nationally, the project supports the expansion of the electric vehicle market and renewable energy sectors by providing a reliable supply of high-quality batteries. Additionally, by enhancing local production capabilities, the project reduces dependency on imported batteries and contributes to India's goal of becoming a leader in sustainable energy solutions.

Explore More

Each project reflects our dedication to pushing the boundaries of what’s possible and creating solutions that meet the highest standards of quality and innovation. Explore our recent work to see how Gorle Global Group is shaping the future of industries and making a positive impact on the world.

Get In Touch

For more information about our projects or to discuss how we can collaborate on your next venture, please contact us at infogorle@gmail.com or info@gorleglobal.com. We look forward to exploring new opportunities together.